Welcome to Scissors Way, your trusted tool maker. We sell the very best Japanese Stainless Steel Hair Scissors globally. This material is known as the top choice for cutting. It gives the sharpness experts must have. Using this strong steel means a perfect cutting edge. Our process respects the old ways of Japanese steelwork. You get a perfect mix of strength and bend. This strong design lasts for many years in the salon.

We only use high-grade steel like 440C and VG10. These metals hold their sharp edge for months. Cheap steel loses its sharpness too fast. Our top tools make cutting easy and clean. Every pair of our steel tools is heat-treated. This heat process makes the blade perfectly hard. We check the steel quality of every single batch.

Our promise on material quality is firm. Buying these strong cutting tools is a smart move. These tools will work well for your whole career. We have many lengths and styles ready to buy. You can choose straight or blending models easily. Trust us for tools that fit your high skill. We offer the best Japanese Stainless Steel Hair Scissors.

Overview of High-Carbon Cutting Tools

Key Features and Benefits

Our cutting tools give long-lasting performance. The main benefit is the sharp, clean cutting edge. This edge makes cutting smooth and quiet. It helps every hair strand cut easily. Stylists save time with these great tools. Our expert salon scissors have comfort handles. The handle shape helps stop hand pain.

You can work all day without soreness. The tension screw allows simple adjustments. You can set the blade tightness as you like. We use smooth turning pivot parts. This makes the blades glide easily. The weight is balanced very well. Good balance gives full control when you cut. We offer bright mirror and dull satin looks.

These looks help keep the steel safe from damage. Our expert tools are light but very strong. This feature lessens strain on your arm. Buying top steel tools improves your work. Your clients will love the healthy, clean results. Our tools help solve daily salon problems.

Material and Build Quality

We use only certified high-carbon steel. This material is trusted around the world. We use VG10 steel for the best use. We also have strong 440C grade steel. Both materials are made to stay very sharp. Our expert shears fight rust very well.

Salon cleaners and water do not hurt them easily. Cheaper metal would break down quickly. Our building quality is solid and reliable. We never use soft or weak parts. The hardness is important for the cutting edge. We keep the HRC between 59 and 62. This hardness stops the edge from getting dull fast.

We use special cold treatment for the steel. This process makes the metal structure better. It greatly increases the life of the cutting edge. The shear parts are put together with great care. We check that the blades meet exactly right. Every part is made to last a long time. You can trust our high-quality process.

Applications and Use Cases

These tools are important for all hair jobs. They are the main tool in high-end salons. Daily work needs reliable and tough tools. Our steel shears cut all hair types well. They cut through thick hair and thin hair cleanly. Mobile experts like the easy-to-carry style. They are tough for constant use and travel.

Barber shops need sharp blades for blending. Careful cutting is key for men’s hair styles. You can use these shears for any client. They work great on both wet and dry hair. Hair school students learn with these tools. Students need strong tools that keep their value.

Our cutting tools are good for new users. They are expert-level for skilled masters. You can supply beauty schools with kits. Students need strong tools to learn well. Our professional shears fit every need perfectly. They are the best tool in any salon. You can sell them to all expert markets.

Product Range and Variants

Different Sizes or Models Available

We have a big choice of cutting lengths. Every expert has a favorite size. Some like short shears for detail work. We make the standard 5.5 and 6.0-inch models. These are best for detail cuts and styling. Our choice includes longer cutting tools. We sell 6.5 and 7.0-inch barber shears.

Longer blades help finish haircuts faster. We also make great thinning tools. Thinners have different teeth amounts. This changes how much hair is removed. Texturizing tools give soft, natural looks. We also make specific left-handed tools.

Left-handed experts need special comfort designs. You can order mixed kits for sales. This lets your buyers have many options. Our expert tools cover all cutting types. You can keep a full stock of sizes easily. We make sure every tool works very well.

Special Features or Upgrades

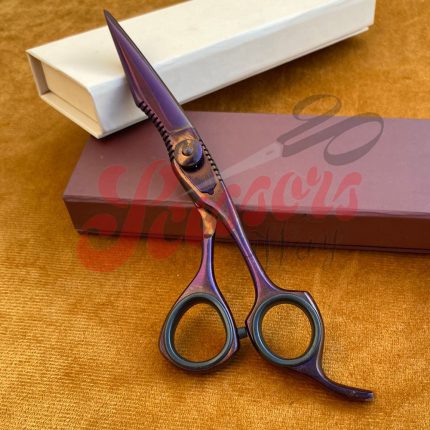

You can ask for helpful extra features. We offer nice color coatings for protection. Colors include black, gold, and pink-gold looks. This coating adds style and protection. It also fights salon cleaning liquids. Our expert tools can have a spinning thumb ring.

The spinning thumb helps stop wrist pain. This is key for not getting hurt at work. We also offer tiny teeth on the blade edge. These teeth stop hair from slipping when cutting. This is great for making straight, blunt lines.

You can get a better screw system. We have fancy decorative screws. We also use smooth moving pivot parts. You can choose different handle shapes for comfort. These shapes help improve how you hold the tool. We build the shears to your exact needs. These features make the tool much more valuable.

Compatibility with Other Products

Our cutting tools fit well into sets of tools. You can sell them as complete kits. A kit can have combs, razors, and clips. Our shears match our own brand of combs. We ensure the colors look the same on all items. They fit easily into standard tool cases.

You can pack them with salon capes. They work with magnetic tool strips on the wall. The stainless steel is easy to sharpen. Good sharpeners can fix our material easily. You can sell shear oil as an extra item. Oil keeps the pivot moving freely.

Cleaning cloths are a good useful extra. We can put your logo on these cloths. Our products help create a very clean brand look. Buyers like to get a complete matching set. This helps you sell more items at once. Our quality shears are the main product. All extras help sell the main tool. We make sure everything looks consistent.

Manufacturing and Quality Assurance

Production Process

Our process uses skill and new technology. We start with certified steel blocks. Skilled workers shape the steel with great care. Shaping makes the metal strong inside. This makes the finished tool very tough. Then we treat the steel with high heat.

This heat process sets the perfect hardness. Next, machines grind the blades carefully. Machines ensure all blade angles are right. Then expert workers sharpen the edges by hand. Hand sharpening makes the edge super sharp. Machines cannot do this fine work.

We put the shears together with close care. We install the tension system well. The final tool is balanced and lined up. The blade tips must close without any gap. Finally, we finish the outer surface. This gives the tool its final look. Making expert tools takes great skill. We respect this process completely.

Certifications and Standards

We follow high quality rules around the world. Our factory runs with high efficiency. We follow all ISO quality guidelines strictly. This makes sure every order is the same high quality. Our steel is bought with full papers. We check the origin and content of the material. Our expert tools are safe and clean.

They have no bad or dangerous stuff inside. The outer colors are safe for use. We follow fair work and ethical rules. Our workers are safe in their jobs. Ethical work is a core belief here. Buyers trust suppliers who work fairly.

You can sell our tools with total trust. We meet all export rules globally. We follow all safety and trade laws. Our packing is done with care for the Earth. We try to use less plastic where we can. Choosing our shears means choosing quality. We handle all the detailed paperwork. You just focus on your sales.

Quality Testing and Reliability

Testing is the most important final step. We test every single shear for cutting. We use real hair for the cutting trials. The shear must cut smoothly without stopping. We check the tension settings very well. It must feel right, not too tight or loose. Our steel tools are tested for strength.

We ensure the steel is not weak. We look at the surface for any small marks. The final logo is checked for clearness. The branding must look perfect and straight. We check all parts fit well.

Any bad tool is taken out right away. It is not sent to the customer. Reliability is our firm promise to you. Your good name depends on our quality. Our expert tools work great every time. This means you will have very few returns. This saves you time and money.

Shipping, Delivery, and Support

Global Shipping Options

We send our tools to customers everywhere. We use strong companies like DHL and FedEx. These services offer fast air delivery. You get large orders quickly. For the lowest cost, we offer sea shipping. Sea shipping is best for the largest orders. Our tools are packed with great care.

We use strong outer boxes for safety. Each shear is wrapped to be safe. We manage all shipping papers needed. We give tracking numbers right away. You can watch your delivery online easily. We understand different countries’ trade rules.

This helps avoid delays at borders. We offer delivery right to your door. You do not have to handle any complex tasks. We manage the shipping fully for you. Our main goal is safe and quick arrival. Your products will arrive ready to sell. We insure all shipments against damage.

Lead Times and Availability

We keep popular styles in stock always. Standard tools can be shipped very fast. Custom logo orders need a little more time. We need time for careful logo work. Production time depends on how many you order. It is usually 3 to 4 weeks for custom work. Our making process is very fast.

We give you a clear shipping timeline.

For big customers, we plan supply ahead. We can send small parts of the order first. This helps keep your shelves stocked well.

We work all year without long breaks. You can rely on our supply always. Having stock is key to good sales. We help you manage your inventory. Trust us for your premium steel tools. We are a reliable partner for you.

Frequently Asked Questions (FAQs)

Customization or Modification Options

Q: Can I request different handle colors?

A: Yes, we can color the handles with coating.

Q: What file type works best for my logo?

A: Vector files like AI are best for clean engraving.

Q: Can I mix different sizes in my order?

A: Yes, you can mix sizes to meet the total count.

Material, Durability, and Safety

Q: What does the HRC number mean?

A: Higher HRC means the blade stays sharp longer.

Q: Why is the convex edge better?

A: It lets the stylist cut smoothly and cleanly.

Q: Are the shears easy to adjust?

A: Yes, the external screw lets you adjust them easily.

Ordering, Bulk, and Shipping Policies

Q: What is the smallest order I can place?

A: Our minimum order is usually 50 tools.

Q: How do I get a price for a big order?

A: Send us your full needs using our form.

Q: Do you ship worldwide?

A: Yes, we offer fast shipping to many countries.

How to Order or Get a Quote

Contact and Inquiry Form

Starting your order is very simple. Please fill out our short inquiry form now. Give us your name and business email. Tell us the models and how many you need. Mention any special branding requests clearly.

Please send us your final logo file. Vector files are best for the sharpest engraving. We promise to reply within one day. We will send you a full price quote. You can also message us directly. Talking easily helps avoid mistakes.

Our expert sales team is ready to help you. We understand the expert tool world well. Please ask any question you have. We are here to help you choose. We make the ordering process simple. Contact us for your price quote today. Let’s work together for quality.

Bulk and Wholesale Discounts

We offer low prices for buying in bulk. Your cost per tool goes down when you buy more. We use a clear pricing system. Small buyers get good wholesale rates. Large companies get the lowest factory price. Our expert tools allow for high sales profit.

We want to help your business get big. We support you with the lowest prices. Ask for our discount list today. Compare our quality and price to others. You will see we are the best choice.

We are honest about all fees. You will not have surprise costs later. We want long-term business friendships. We give extra savings to repeat buyers. Working with us is a very good choice. Buy our quality tools to grow your business.

Sample or Demo Requests

Testing the tool is the first step. We suggest ordering samples first. Choose the exact tools and sizes you want. We will ship the samples quickly to you. Test the sharpness on real hair. Feel the comfort in your hand.

Check the expert quality of the steel. You will clearly see our promise to quality. The sample cost is given back to you. We take this money off your first big order. This makes testing our product completely safe. It is the best way to check our tools.

We are fully sure you will love our tools. We start big production only after you approve. This ensures you get exactly the tools you wanted. Ask for your sample kit right now. See the expert quality today.

| Specification | Details |

| Product Name | Expert Japanese Steel Shears |

Manufacturer |

Scissors Way |

| Type | Cutting, Thinning, Blending |

| Blade Type | Japanese Convex Edge |

| Steel Grade | 440C, ATS-314, VG10 Steel |

| Customization | Logo, Screw, Color |

| Sizes | 5.0″, 5.5″, 6.0″, 6.5″, 7.0″ |

| HRC (Hardness) | 59-62 Rockwell Hardness |

| Edge Retention | Very Good |

| Country Of Origin | Pakistan (Using Best Steel) |

Reviews

There are no reviews yet.